CEREL strategic goal is to find industrial partners in the country and abroad interested in implementation of ceramic elements for machines and devices.

Ceramic Department CEREL is one of the four independent units of the Institute of Power Engineering in Warsaw, existing since 1972. Our headquarter is located in Boguchwała near Rzeszów.

Activity of CEREL began in the 1960s as the Research and Development Department at Electrotechnical Porcelain Plants ZAPEL, which dealt with electrotechnical porcelains and the insulators manufacturing technology. In 1972, the independent Research and Development Centre of Electrotechnical Ceramics CEREL was established, which carried out work on the technology development and the equipment design for the electrotechnical porcelain production. In 1992, CEREL was incorporated into the Institute of Power Engineering as Ceramic Department CEREL, which changed its business profile and began working on the new ceramic materials development and the special ceramics production techniques for machines applications and devices operating in a chemically aggressive environment, subject to rapid wear. Over the last several decades, CEREL has become a leading manufacturer of ceramic products made of structural and functional materials with great research potential.

CEREL strategic goal is to find industrial partners in the country and abroad interested in implementation of ceramic elements for machines and devices.

Our competences in the field of advanced structural ceramics have allowed our partners and customers to implement a whole range of solutions based on complex and extremely difficult to machine parts. These solutions have repeatedly contributed to the achievement of previously unattainable levels of efficiency and reliability by their machines, devices and production lines.

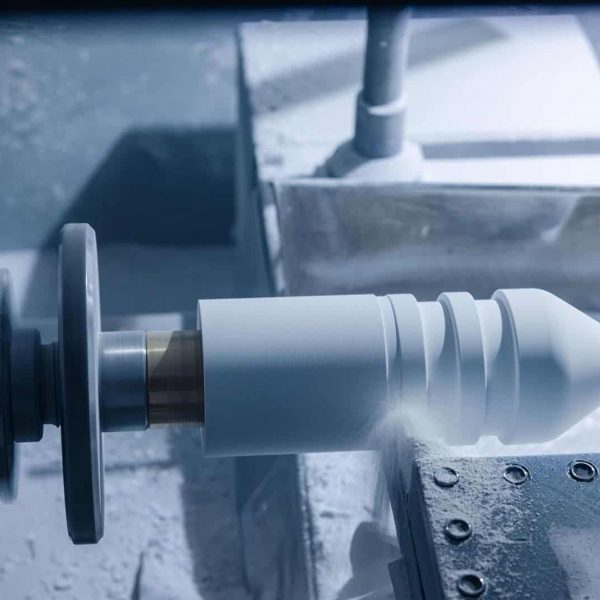

CEREL is structural and functional ceramic products manufacturer mainly zirconia, alumina, nitrides, carbides, technical porcelain, mullite, steatite and cordierite. Our advanced structural ceramics is characterized by excellent mechanical properties, high abrasion resistance, high hardness, chemical corrosion resistance, low coefficient of heat conduction and stability in high temperature operation. Ceramic parts of machines and devices, insulating elements, advanced refractory ceramics elements produced by CEREL are used in the aviation superalloys casting, laboratory ceramic elements and many other products find recipients both in country and abroad in the aviation, automotive, chemical, power engineering, metallurgical, wood, paper, steel, foundry, refractory, glass, food and pharmaceutical industries. Such wide range products manufacturing from advanced technical ceramics is possible due to equipment that allows ceramic materials production with practically whole forming techniques used in the world (uniaxial pressing, isostatic pressing, extrusion, slip casting, tape casting, screen printing, low and high pressure injection moulding and many others). CEREL is equipped with modern numerically controlled machines for processing semi-finished products after forming (lathes, milling machines, drills, plotter, laser) and after sintering (grinders, milling machines) as well as a coordinate measuring machine to control the high-precision products performance.

Beside production activities, CEREL conducts research and development in the field of modern ceramic materials, ranging from the powders producing methods to precise mechanical processing of sintered products. CEREL's scientific activity covers issues related to fuel cells, perovskite materials, oxygen membranes, refractory materials, advanced ceramics, ceramic cores, ceramic coatings, foundry filters and catalysts. CEREL research and development department employees actively participate in the implementation of international research projects financed by European Union programs and nationally financed by the Ministry of Education and Science, the National Centre for Research and Development, the National Science Centre, as well as in implementation works for industry.

CEREL is equipped with an extremely modern laboratory to support our ceramics development activities and ensure our production materials are within the very stringent specifications required to achieve our exacting standards.

CEREL is a member of the Aviation Valley, the Subcarpathian Hydrogen Valley and the Subcarpathian Renewable Energy Cluster.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur vulputate posuere tortor luctus vulputate. Cras laoreet pretium blandit. Vestibulum luctus laoreet lacinia. Maecenas luctus arcu ut orci lacinia ultrices. Praesent semper porta interdum. Etiam cursus, tortor at interdum rutrum, metus nibh tincidunt purus, non tincidunt odio arcu quis erat.

Curabitur vulputate posuere tortor luctus vulputate. Cras laoreet pretium blandit. Vestibulum luctus laoreet lacinia. Maecenas luctus arcu ut orci lacinia ultrices. Praesent semper porta interdum. Etiam cursus, tortor at interdum rutrum, metus nibh tincidunt purus, non tincidunt odio arcu quis erat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur vulputate posuere tortor luctus vulputate. Cras laoreet pretium blandit. Vestibulum luctus laoreet lacinia.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur vulputate posuere tortor luctus vulputate. Cras laoreet pretium blandit. Vestibulum luctus laoreet lacinia. Maecenas luctus arcu ut orci lacinia ultrices. Praesent semper porta interdum. Etiam cursus, tortor at interdum rutrum, metus nibh tincidunt purus, non tincidunt odio arcu quis erat.

Curabitur vulputate posuere tortor luctus vulputate. Cras laoreet pretium blandit. Vestibulum luctus laoreet lacinia. Maecenas luctus arcu ut orci lacinia ultrices. Cras laoreet pretium blandit. Vestibulum luctus laoreet lacinia.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur vulputate posuere tortor luctus vulputate. Praesent semper porta interdum. Etiam cursus, tortor at interdum rutrum, metus nibh tincidunt purus, non tincidunt odio arcu quis erat.

Curabitur vulputate posuere tortor luctus vulputate. Cras laoreet pretium blandit. Vestibulum luctus laoreet lacinia. Maecenas luctus arcu ut orci lacinia ultrices. Praesent semper porta interdum. Etiam cursus, tortor at interdum rutrum, metus nibh tincidunt purus, non tincidunt odio arcu quis erat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur vulputate posuere tortor luctus vulputate. Cras laoreet pretium blandit. Vestibulum luctus laoreet lacinia.