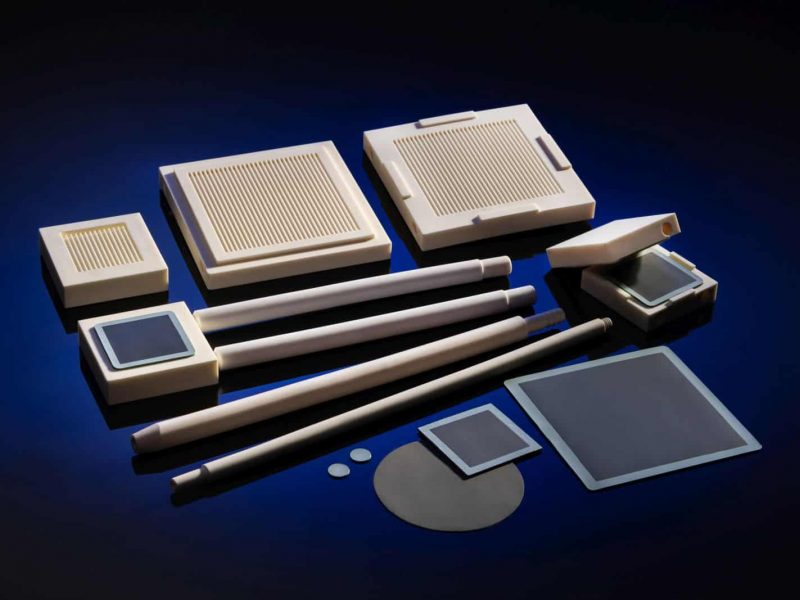

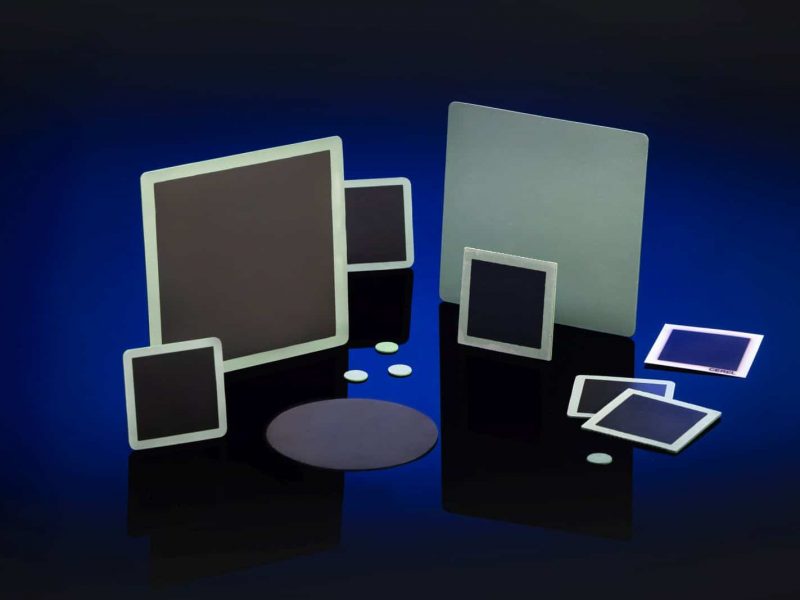

1. Fuel cells, electrolysers

Anode Supported Solid Oxide Fuel Cells (AS-SOFC), Solid Oxide Electrolyser Cells (SOEC)

The supports of solid oxide fuel cells and solid oxide electrolyser cells are manufactured in Ceramic Department CEREL with the use of innovative method of high-pressure injection moulding method (HPIM), and functional anode and cathode layers and electrolyte layers using efficient thin-layer methods. Compared to the commonly used tape casting method, the use of the thermoplastic moulding method allows significant reduction of production costs by shortening the production time and reducing production losses, and allows obtaining fuel electrode supports with much higher repeatability of dimensions and electrochemical parameters. The use of high-performance production technologies allows for the production of large series of cells with repeatable parameters, characterized by high parameters of mechanical and electrochemical properties. Ceramic Department CEREL produces fuel cells with various layer configurations, with dimensions up to 110 mm x 110 mm. We manufacture cells based on a fuel electrode support with the basic composition of nickel oxide NiO and zirconium dioxide stabilized with yttrium oxide YSZ.

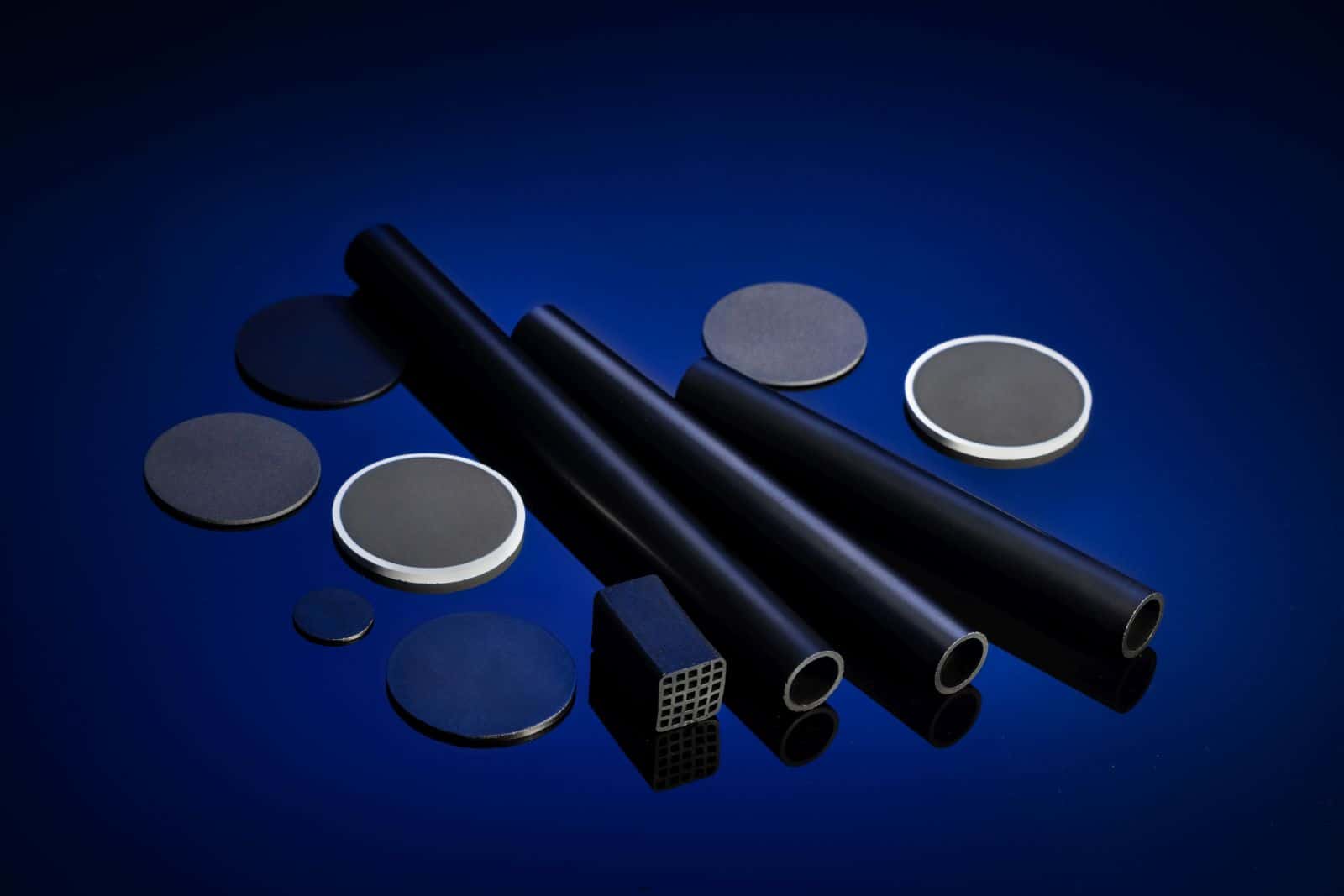

2. Oxygen membranes

CEREL has been leading research on perovskite materials and dense oxygen membranes manufactured from them for production pure oxygen from air and oxy-combustion processes, for over fifteen years. A complete technology for obtaining dense oxygen membranes was developed, beginning from perovskite powders production by the solid state and spray pyrolysis methods, through forming various membranes shapes by both uniaxial and isostatic pressing as well as extrusion, ending at sintering and grinding process. The produced by us oxygen membranes have disc-shape, tubes and a developed complex surface. The obtained results of the oxygen permeation fluxes through membranes are at the level of data reported by other authors in the world literature, and the long-term oxygen permeation flux test lasting two thousand hours confirmed the stability of the manufactured membranes performance.